Description

Sand sample analysis of target zone of Panyu XX oil field shows that formation grain median size (d50) is 240 um to 630 um, non-uniform coefficient of formation sand is equal to 2.5,with good sorting behavior; formation sand is uniform, mostly are medium and fine sand. The field formation crude oil viscosity is 3.8 ~ 132 mPa.s, porosity distribution 17.9% ~ 29.2%, permeability distribution 444.5 ~ 6042.7 mD, reservoir temperature 74 ~ 111 ℃, the initial formation pressure 14.5 ~ 26.2MPa, belonging to medium - high porosity and extra-high permeability reservoir.

We performed the Panyu XXoil field adjustment well project as an integrated service for lower completion section, there are 55 wells totally. Panyu XX platform has 25 wells with average horizontal section length is of 538m and average depth of 2724m. Panyu XX platform has 30 wells with average horizontal section length is of 581m and average depth of 2831m. STARSE Bridging Composite Screen of 16,370m and STARSE Variable Density Stellar Screen of 13,630m are used as well as 55 sets of completion tools, including SNTP top packer, SQC quick connection and SDW dual-way washing device etc.

This project has long operation cycle, difficult operation, high technical requirements and strict management. Panyu XX project 55 wells are completed smoothly in 2014. The project has achieved great achievements and has been fully recognized and highly valued by customer. Self-developed top packer and new tools such as dual-way washing device, and the application of new technology greatly shorten the lower completion period, the average single well operation time saving more than 5 hours, improving operation efficiency and achieving zero accident. We have received highly appreciation from the customer.

Single well case study: Well PY4-XX

1. Completion method

It is designed as standalone premium screen completion in 8 1/2〞borehole.

Figure 1 Schematics of Completion

2. Application Effects

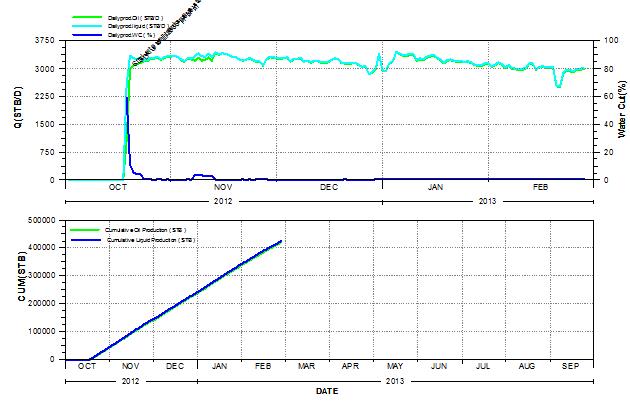

The well was officially put into production on October 18, 2012. The initial production drawdown pressure was about 260Psi, and the maximum daily fluid volume reached 3400STB/D. At present, the daily fluid volume is about 3000STB/D. The production situation is normal without sand production. The sand control has achieved the ideal effect.

Figure 2 Production Curve of Well PY-XX

3. Honors and Rewards

Excellent Service Provider Awards from Customer