Description

Well Dingye-5 sidetracking horizontal well is a deep shale gas well in the Dingshan structure developed by of Sinopec exploration branch. Drilled depth of this well is 5685 m, vertical depth of 4145.41 m, horizontal section length of 1520 m, bottomhole temperature of 133 ℃, production casing depth of 5682 m with configuration of casing size φ139.7mm×TP125SG×12.7mm. The well has the characteristics of deep burial depth, high formation temperature, high pressure of fracturing pump and high risk of tubular pumping.

| Well Name |

Well Dingye-5 sidetracking horizontal well |

Well Type |

Exploratory Well |

| geographical location |

Wantou Formation, Zhenhexin Village, Zhaiba Town, Xishui County, Guizhou Province |

|

· tectonic location

|

The northwest wing of Dingshan Structure, Lintan field - Dingshan northeast Structure Belt, Southeast Sichuan. |

| Line position |

A:Line 2527,Trace2194; B:Line 2553,Trace 2124 |

| · ground elevation (m) |

1010.6m |

Kelly Bushing Elevation(m):1021.1m |

Kelly Bushing Height(m):10.5 |

| Design Depth (m) |

MD:5685.00, VD:4134.00 |

| Spud Date |

2017-5-8 |

Operation Crew |

Drilling Crew 70168SL,

Southwest Branch of Shengli Petroleum Engineering Co., Sinopec

Drilling Crew HN004,

Huabei Petroleum Engineering Co., Sinopec |

| Drilling Completed Date |

2017-6-29 |

Drilling Completed Depth (m) |

MD:5685.00,VD:4145.41 |

| PBTD |

5634m(MD) |

| Completion Date |

/ |

Completion Method |

Casing completion |

| Bit Program (mm×m) |

Casing Program(mm×m) |

Casing Grade & Wall Thickness |

Cement Top(m) |

| φ311.2mm×3896m |

Φ244.48mm×3894.00m |

P110×11.99mm |

Surface |

| φ215.9mm×5685.00m |

Φ139.7mm×5682.00m |

TP125SG×12.7mm |

Surface |

Table 1 Basic Data of Well Dingye-5 Sidetracking Horizontal Well

Solution

The whole well is perforated with wireline perforating gun + frac&plug technique. The trajectory is stable and 20 fracturing stages are used, all of which were equipped with the ball-type fully dissolvable bridge plug provided by STARSE.

In the first stage, the coiled tubing perforation is used, and the remaining 19 fracturing stages are performed by bridge plug & perforation technique, and the whole well are equipped with19 ball-type fully dissolvable frac plugs which is provided by STARSE. After each fracturing, wireline and dissolvable plug as well as perforation gun and charge are pumped to preset depth, ignite to set bridge plug and release, then pull perforation gun to preset depth to perforate, finally pull out of wireline to perform fracturing operation. Perforation gun of Ф89mm is selected with pressure rating more than 140MPa (WP) . Hole density is 16hole/m, phase position of 60° , perforation hole diameter ≥13.9mm, casing coupling perforation shall be prohibited. The maximum pressure of the wellhead in the fracturing operation is 110MPa (50MPa on the bridge plug), the highest single-stage fracturing fluid volume is 2818.8m3, the total well accumulates the well fluid amount of 50000m3, and the bridge plug can still ensure the seal effectively after 24 hours. After the completion of fracturing, it was successfully flowback and drainage, and run into the coiled tubing to confirm all the dissolvable bridge plug was completely dissolved, realizing the full diameter of the wellbore.

STARSE’s ball-type dissolvable fracturing plug is used to perform staged fracturing operation, it features: simplifies operation procedure, perforation test is made valid by means of the seal to ensure all bridge plug setting are effective, saves the pumping time and amount of liquid and eliminate plug drilling risk in deep high pressure gas well. Compared with the previous products, STARSE’s ball--type dissolvable frac plug technology is low cost, safe and reliable.

Features

Ø Using dissolvable frac plug and wireline&perforation, large scale hydraulic fracturing and multistage fracturing can be achieved.

Ø Can realize fixed-point selectively perforating and fracturing.

Ø Special design satisfies the requirement of pressure testing inspection seal and guarantee effectiveness of isolation.

Ø After fracturing, there is no need for wellbore intervention, nearly no residuals.

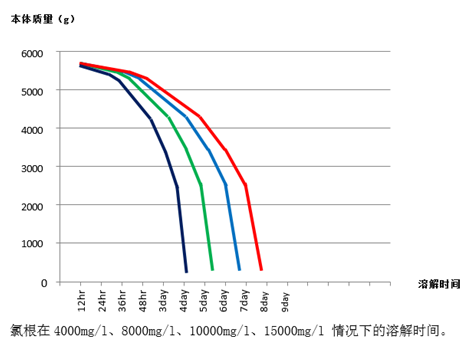

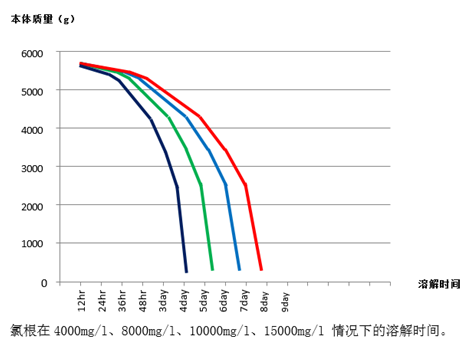

Ø After fracturing, the bridge is dissolved for 5-10 days (according to the calculation of concentration of chlorine in the formation return liquid) to maintain the borehole unblocked and facilitate the post-operation.

Ø The material is dissolved quickly and evenly, and the dissolved slag is easy to be flowback. The fracturing scale is very large, and can be more than 10 stages.

Ø Can be used in large shale gas and coalbed methane fracturing.

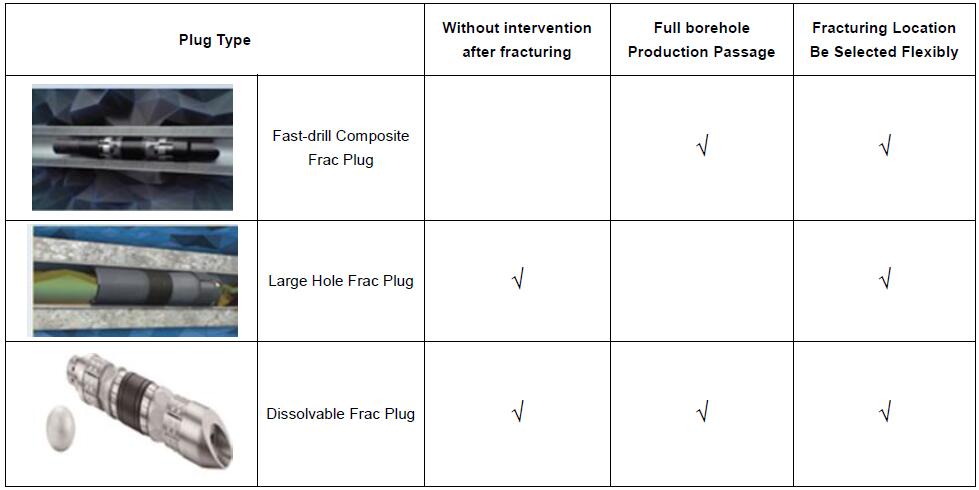

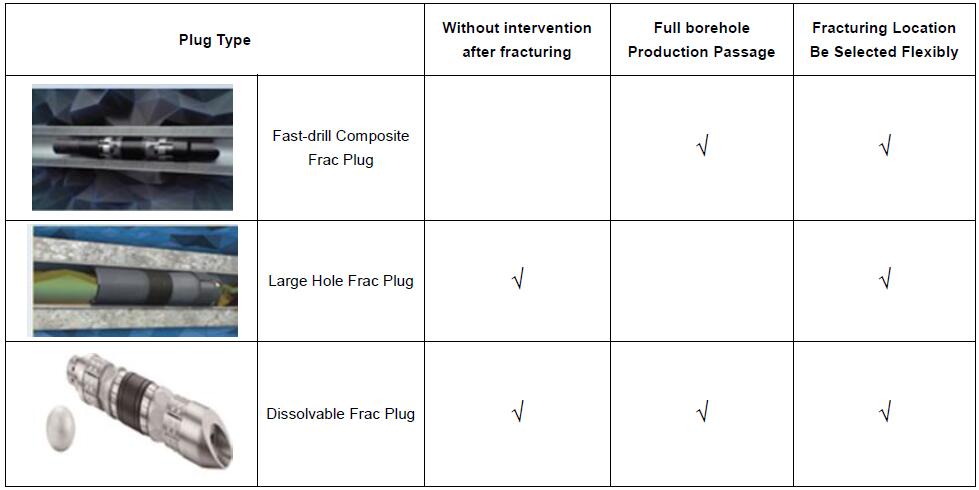

Table 2 Technique Comparison of Bridge Plug with Different Functions

| |

Fast-drill Composite Frac Plug |

Large Hole Frac Plug |

Dissolvable Frac Plug |

| Milling Economy |

Long milling time;

High milling risk;

Big problem of debris problem |

/ |

/ |

| Equipment Requirement |

Coiled tubing is required; crawler and resistance reduction measures are needed |

/ |

/ |

| Post-Treatment |

Keep full bore |

Milling is needed for secondary treatment |

Keep full bore |

| Economy |

Bridge plug+ special coiled tubing + crawler+ resistance reducer |

Bridge plug+milling cost in late stage |

Bridge plug |

Table 3 Cost Comparison of Bridge Plug with Different Functions

Figure 1 Dissolution Curve of STARSE’s Dissolvable Bridge Plug

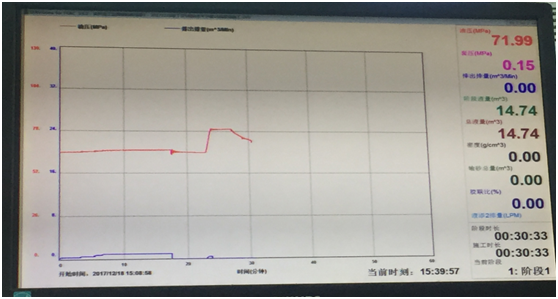

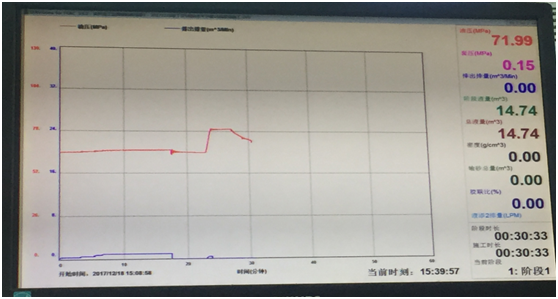

Figure 2 Operation Curve

Figure 3 Pressure Test Curve